Over View

Main Products

Waste Tyre Recycling

Bitumen Production

The world's lightest body armour to be made in Malaysia

By replacing Kevlar with coconut leaf sheath, the cost was slashed almost in half

Typically, bulletproof vests are just normal vests with bulletproof plates in them, and a common bulletproof plate consists of three layers: a ceramic plate, layers of a fabric woven from a synthetic fiber called Kevlar, and a metal alloy plate. When a bullet hits this plate, the ceramic plate breaks on impact, and the Kevlar fibres further slows down the bullet, dissipating the impact.

Kevlar is a pretty pricey fibre, though, with its raw materials alone being said to cost somewhere between five to twenty times the raw materials for fabrics like nylon and polyester. Dr Jawaid had been researching natural fibres, and after comparing fourteen types of natural fibers, his team found that the one best suited for stopping bullets is a relatively useless part of the coconut tree: the leaf sheaths.

Coconut leaf sheaths (left) and Kevlar 29 (right) samples.

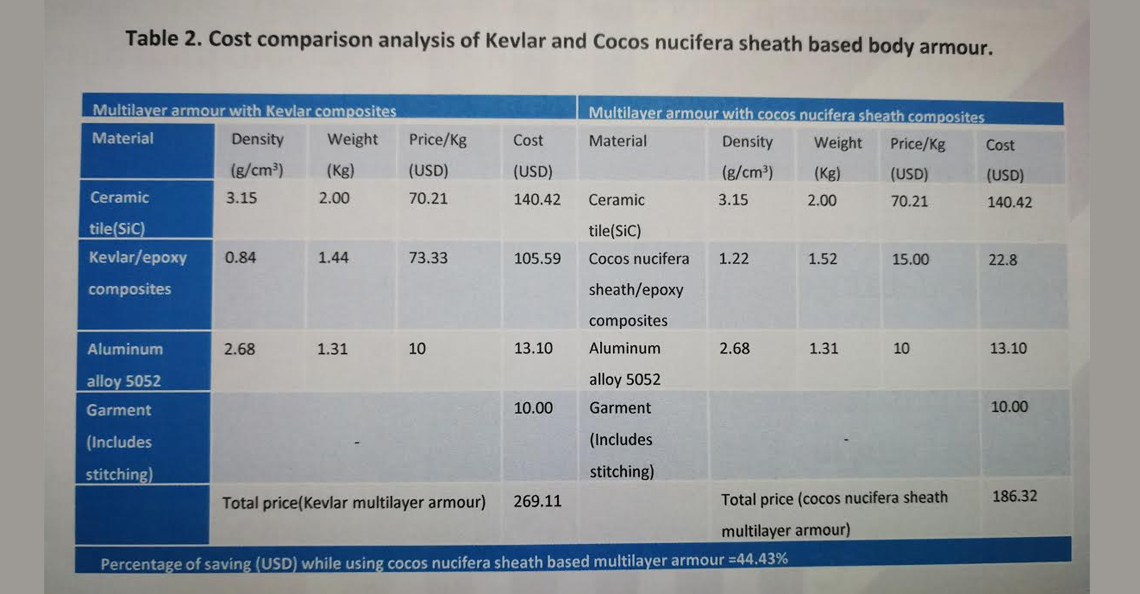

By replacing Kevlar with coconut leaf sheath, the estimated raw material cost is reduced almost by half, or 44.43% if we’re being picky.

Cost and weight comparison for the two types of body armor they made.

Interestingly, after experimenting with combinations of coconut leaf sheaths and Kevlar as well as coconut leaf sheaths improved with graphene (which are costly as well), but it was found that just plain coconut leaf sheaths do the job better.

“Previously we’ve also done Kevlar and coconut… we’ve also done modifications on the coconut using graphene nanoparticles to improve the property… but we found that the non-graphene one is better.” – Dr Mohamad Jawaid, to Cilisos.

Despite being cheaper, coconut leaf sheath in armor is almost as effective as Kevlar

Dr Jawaid’s team came up with a name for the innovation already: the Techno-Economic Hard Body Armor, or TEHBA. And the one in the picture isn’t really the final version; it’s a prototype of sorts, with improvements to the design planned in the future.

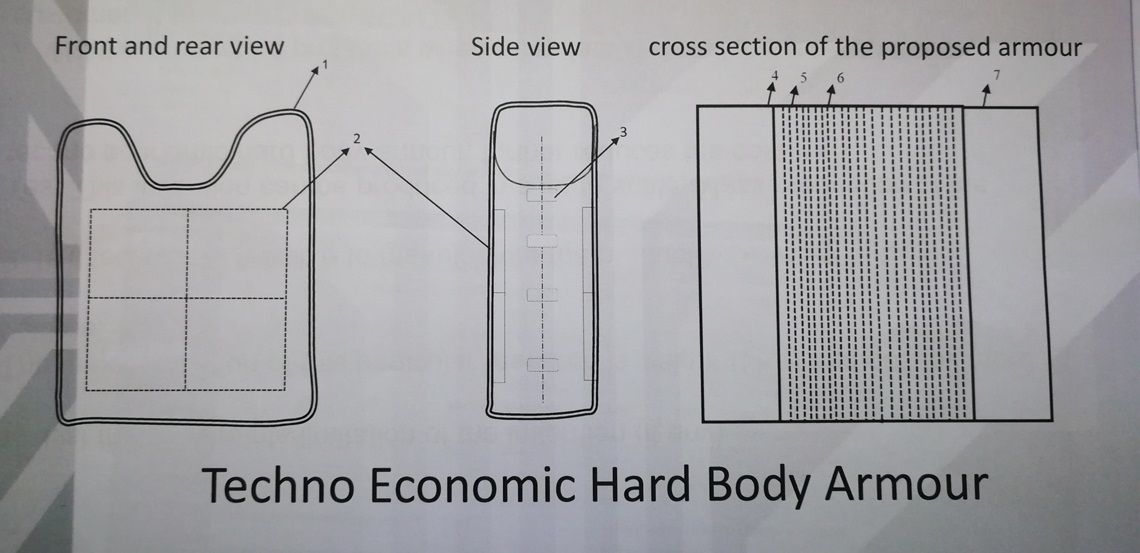

The basic TEHBA design.

Anyways, as we’ve said earlier, bulletproof vests work by dissipating the force by an approaching bullet, which means that it makes a gunshot feel less like a piercing spear and more like a blunt hammer.

Wearing a bulletproof vest will hopefully stop bullets from piercing your skin and damaging the organs underneath, but some damage will still happen. The measure of a good bulletproof vest is how shallow the resulting damage is, and this is measured through something called the backface signature. To do this test, you basically put the bulletproof material in front of a block of clay, then shoot into the material. The depth of the resulting crater is then measured to give you the backface signature.

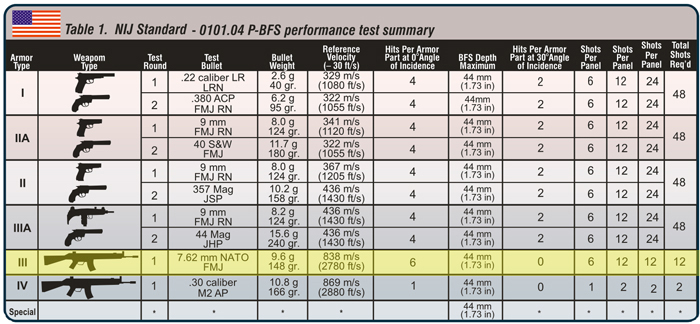

In a test, Dr Jawaid’s team fired a 7.62 mm caliber bullet into both the TEHBA and a Kevlar ballistic plate from 15 meters away, at a velocity of roughly 838 m/s. As for why these numbers are chosen, they appear to be the prerequisites for the National Institute of Justice (NIJ) standard for Type III armor.

Essentially protecc against rifles and everything above it. Img from Europe Armor.

As you can see from the table, there are more things to the actual test than just the size and speed of the bullet, but all of them require that the backface signature (BFS Depth) not go deeper than 44 mm. From Dr Jawaid’s test, the resulting backface signature was 24.12 mm for the Kevlar plate, and a slightly higher 26.51 for TEHBA, both still way below NIJ’s requirements.

Who knows what other uses we can find from our untapped resources?

“We’ve done a lot of research, but because the product did not come, we do not make the news, then people don’t know.” – Dr Mohamad Jawaid, to Cilisos.

Anyhow, knowing the possibilities of natural fibers, a bulletproof vest made from coconut leaf sheaths is probably not the craziest idea out there. With an open mind and some research, we can probably come up with more interesting applications for our less-looked at resources in the future.

Subscribe Now

Don’t miss our future updates! Get Subscribed Today!

©2024. Flyton Intl. All Rights Reserved.

Privacy Policy